Is your manufacturing operation struggling with inefficiencies? Are you looking for ways to boost productivity, reduce waste, and improve your bottom line? The answer may lie in implementing lean manufacturing principles. This article will explore how the lean process can revolutionize your manufacturing operations, driving significant improvements in efficiency and overall performance.

Key Takeaways:

- Lean manufacturing focuses on eliminating waste in all its forms to create a more efficient and productive operation.

- Implementing a lean process involves identifying and addressing inefficiencies throughout the value stream, from raw materials to finished goods.

- Key tools and techniques like Value Stream Mapping, 5S, and Kaizen are essential for successful lean implementation.

- A culture of continuous improvement is crucial for sustaining the benefits of lean manufacturing over the long term.

Understanding the Core Principles of a Lean Process

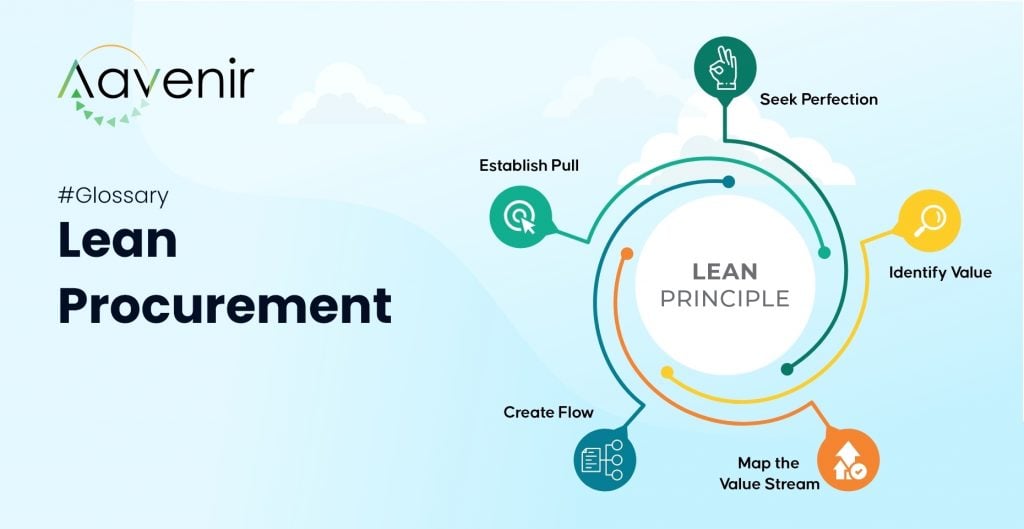

At its heart, lean manufacturing is a philosophy centered around maximizing value while minimizing waste. This involves identifying and eliminating anything that doesn’t add value to the final product from the customer’s perspective. This “waste” can take many forms, often remembered by the acronym “DOWNTIME”: Defects, Overproduction, Waiting, Non-utilized talent, Transportation, Inventory, Motion, and Extra-processing. The goal is to create a smooth, efficient flow of materials and information throughout the entire production process. This approach improves efficiency and reduces the amount of “gb” data stored during the process. This efficiency helps optimize the process.

One of the fundamental tools in implementing a lean process is Value Stream Mapping (VSM). VSM allows you to visualize the entire production process, from raw materials to the finished product in the hands of the customer. By mapping the current state, you can identify areas where waste exists and develop a future state map that outlines how to eliminate that waste. This provides a clear roadmap for improvement initiatives.

Implementing a Lean Process in Your Facility

Implementing lean isn’t just about adopting a set of tools; it’s about fostering a culture of continuous improvement. This requires buy-in from all levels of the organization, from top management to frontline workers. Start by educating your team on the principles of lean and the benefits it can bring. Then, identify a pilot project where you can test and refine your lean implementation strategy.

Some practical steps for implementing a lean process include:

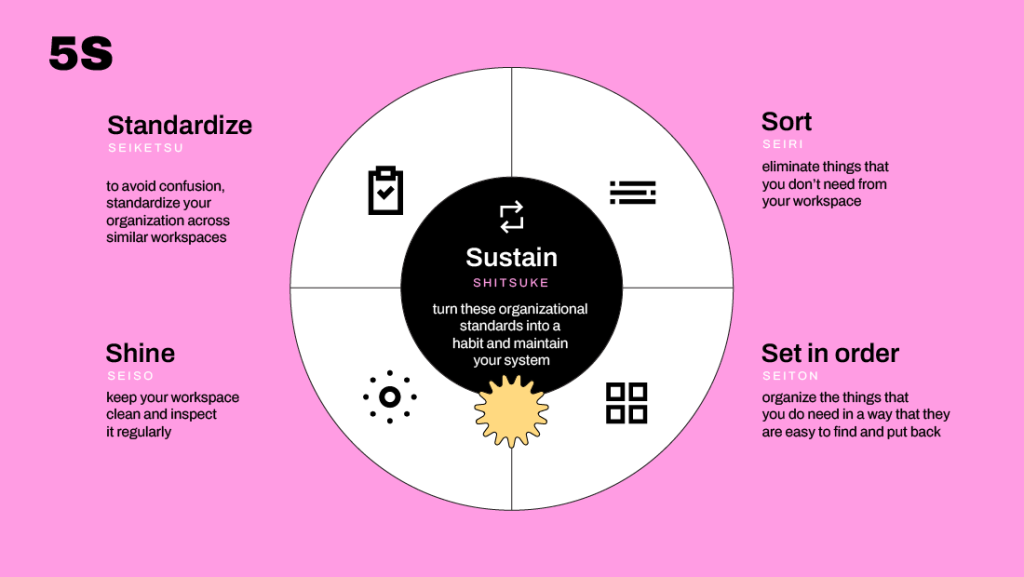

- 5S Methodology: Sort, Set in Order, Shine, Standardize, and Sustain. This helps create a clean, organized, and efficient workspace.

- Kaizen Events: Short, focused improvement projects that bring together cross-functional teams to identify and implement solutions to specific problems.

- Just-in-Time (JIT) Inventory Management: Minimizing inventory levels by producing goods only when they are needed.

- Standardized Work: Defining the best way to perform each task to ensure consistency and reduce variation.

Benefits of a Well-Executed Lean Process

The rewards of successfully implementing a lean process are substantial. Businesses often see significant improvements in:

- Reduced Waste: Eliminating waste leads to lower costs and increased profitability.

- Improved Efficiency: Streamlined processes result in faster cycle times and increased throughput.

- Higher Quality: Reducing defects and variation leads to improved product quality and customer satisfaction.

- Increased Employee Morale: When employees are empowered to identify and solve problems, it boosts morale and engagement.

- Enhanced Customer Satisfaction: Faster lead times, higher quality, and lower prices all contribute to improved customer satisfaction.

Sustaining a Lean Process for Long-Term Success

Lean manufacturing is not a one-time project; it’s a continuous journey. To sustain the benefits of lean over the long term, it’s essential to establish a culture of continuous improvement. This means regularly reviewing your processes, identifying new opportunities for improvement, and empowering your employees to participate in the process.

Regular audits and performance metrics can help track progress and identify areas where further improvement is needed. Celebrate successes and recognize employees who contribute to the lean journey. By making lean a core value of your organization, you can ensure that it remains a driving force for efficiency and success for years to come.